United States

More countries

Menu

Service

Solutions

Sort

Pick

Convey

Store

Industries

Airports

Courier, Express & Parcel

E-Commerce, Retail & Fashion

Food & Beverage

Manufacturing Logistics

Storage & Distribution

Tire & Automotive

Products

Unit Handling

Pallet Handling

Unit Handling

Pallet Handling

Unit Handling

Rollers and Wheels

Drives

Controls

Conveyors

Power Supplies

Sorter

Carton Flow

Pallet Handling

Rollers

Drives

Controls

Modular Pallet Platform

Stacker Crane

Transfer Car

Pallet Flow

Smart Pallet Mover

Tools & Downloads

Tools & Downloads

Software Downloads

Tools & Downloads

Belt Drive Matchmaker - BDMM

CAD Download

Downloads

E-learning

Lifetime Service

Software Downloads

MultiControl

Pallet Control

Company

About Interroll

Technology

Investor Relations

Sustainability

About Interroll

Culture and Values

Corporate Governance

Corporate Compliance

Interroll Academy

Careers

Technology

Centers of Excellence

Innovation Projects and Development Center

Digitalization

MicroHubs

Energy Efficiency

Logistics Industry Outlook

Investor Relations

Stock Information

Reports and Publications

Annual General Meeting

Financial Calendar

Financial Analysts

Alternative Performance Measures

Investor Relations Contact

News service & Press Contact

Sustainability

Sustainability Management

Sustainable Development Goals

Sustainability Report

ESG Download Center

News & Events

Events

News & Press Releases

E-Moving Magazine

PR material / Gallery

References

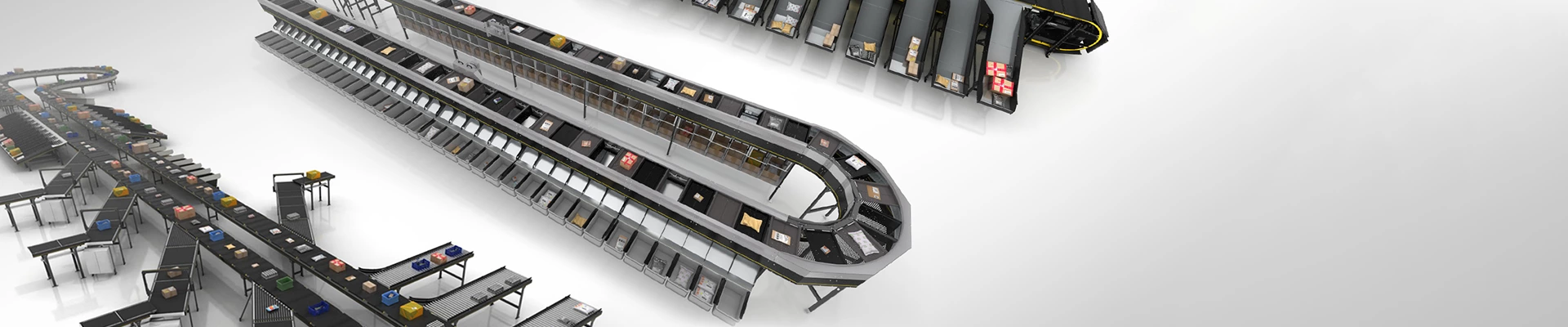

Sorters are needed at various points in intralogistics, such as in the goods receiving, picking and shipping areas. With the Interroll Sorter Solution Platform, Interroll offers a full range of proven solutions for reliable and cost-effective sorting of unit loads such as cartons, parcels, packaged food, etc. In response to the increased global demand for fast sorting technology and the growing variety of goods, Interroll completely innovated and extended their sortation portfolio.

Sorter Structure

Horizontal Vertical9

products match your selection.

Apply next filter or go here to the products.

Item Weight

Up to 50 kg9

products match your selection.

Apply next filter or go here to the products.

Sorter Structure

Horizontal Vertical9

products match your selection.

Apply next filter or go here to the products.

Item Weight

Up to 50 kg9

products match your selection.

Apply next filter or go here to the products.

Find your drive

These 9 products perfectly meet your requirements.

9

products match your selection.

Apply next filter or go here to the products.

Our Sorter Solution Platform offers a full range of proven solutions for reliable and cost-effective sorting of unit loads such as cartons, parcels, packaged food, etc. In response to the increased global demand for fast sorting technology and the growing variety of goods, we completely innovated and extended our sortation portfolio.

Today, around 500 Interroll Sorters are already in use worldwide by industry leaders such as Amazon, DHL, FedEx, UPS, Hugo Boss, Inditex (ZARA), Zalando and the Swiss, Austrian, and Chinese postal systems. Less complex control systems are used for this automation solution.

Therefore, there is no need for expensive installation, maintenance or reconfiguration expertise for the systems. The unique design principle ensures maximum availability, a very long system service life, low operating costs, and fast return on investment.

The crossbelt carrier run on polyurethane coated wheels in aluminium profiles (linear sorter) or on steel tubes (horizontal sorter) and are pulled by a rubber block chain belt.

Once a crossbelt carrier reaches its intended destination, a pneumatically actuated plate makes contact with a drive wheel mounted underneath the chassis of the crossbelt carrier. In this way, the motion of the carrier is converted into driving the crossbelt, bringing the goods gently to their desired destination.