United States

More countries

Menu

Service

Solutions

Sort

Pick

Convey

Store

Industries

Airports

Courier, Express & Parcel (CEP)

E-Commerce, Retail & Fashion

Food & Beverage

Manufacturing Logistics

Storage & Distribution

Tire & Automotive

Products

Unit Handling

Pallet Handling

Unit Handling

Pallet Handling

Unit Handling

Rollers and Wheels

Drives

Controls

Conveyors

Power Supplies

Sorter

Carton Flow

Pallet Handling

Rollers

Drives

Controls

Modular Pallet Platform

Stacker Crane

Transfer Car

Pallet Flow

Smart Pallet Mover

Tools & Downloads

Tools & Downloads

Software Downloads

Tools & Downloads

Belt Drive Matchmaker - BDMM

CAD Download

Downloads

E-learning

Lifetime Service

Software Downloads

MultiControl

Pallet Control

Company

About Interroll

Technology

Investor Relations

Sustainability

About Interroll

Culture and Values

Corporate Governance

Corporate Compliance

Interroll Academy

Careers

Technology

Centers of Excellence

Innovation Projects and Development Center

Digitalization

MicroHubs

Energy Efficiency

Logistics Industry Outlook

Investor Relations

Ad Hoc Press Releases

Stock Information

Reports and Publications

Annual General Meeting

Financial Calendar

Financial Analysts

Alternative Performance Measures

Investor Relations Contact

News service & Press Contact

Sustainability

Sustainability Management

Sustainable Development Goals

Sustainability Report

ESG Download Center

News & Events

Events

News & Press Releases

E-Moving Magazine

PR material / Gallery

References

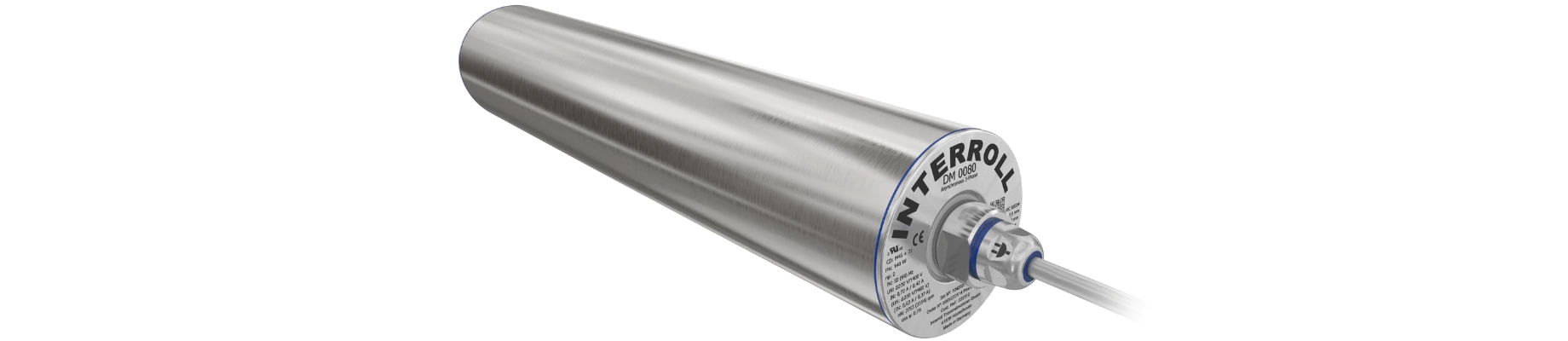

With a wide range of speeds, the DM 0080 covers all conceivable fields of application in the food sector, as well as in industry, distribution and airports. The synchronous motor variant is ideal for highly dynamic applications, conveyor systems in food processing, SmartBelt conveyors and many belt conveyors with servo inverters.

CAD drawings are available in 3D PDF, 2D DWG, IGES, STEP and SAT formats.

DownloadDo you have any questions or would like to know more? Please contact us!

ContactCAD drawings are available in 3D PDF, 2D DWG, IGES, STEP and SAT formats.

DownloadDo you have any questions or would like to know more? Please contact us!

Contact

Flexibility makes the difference!

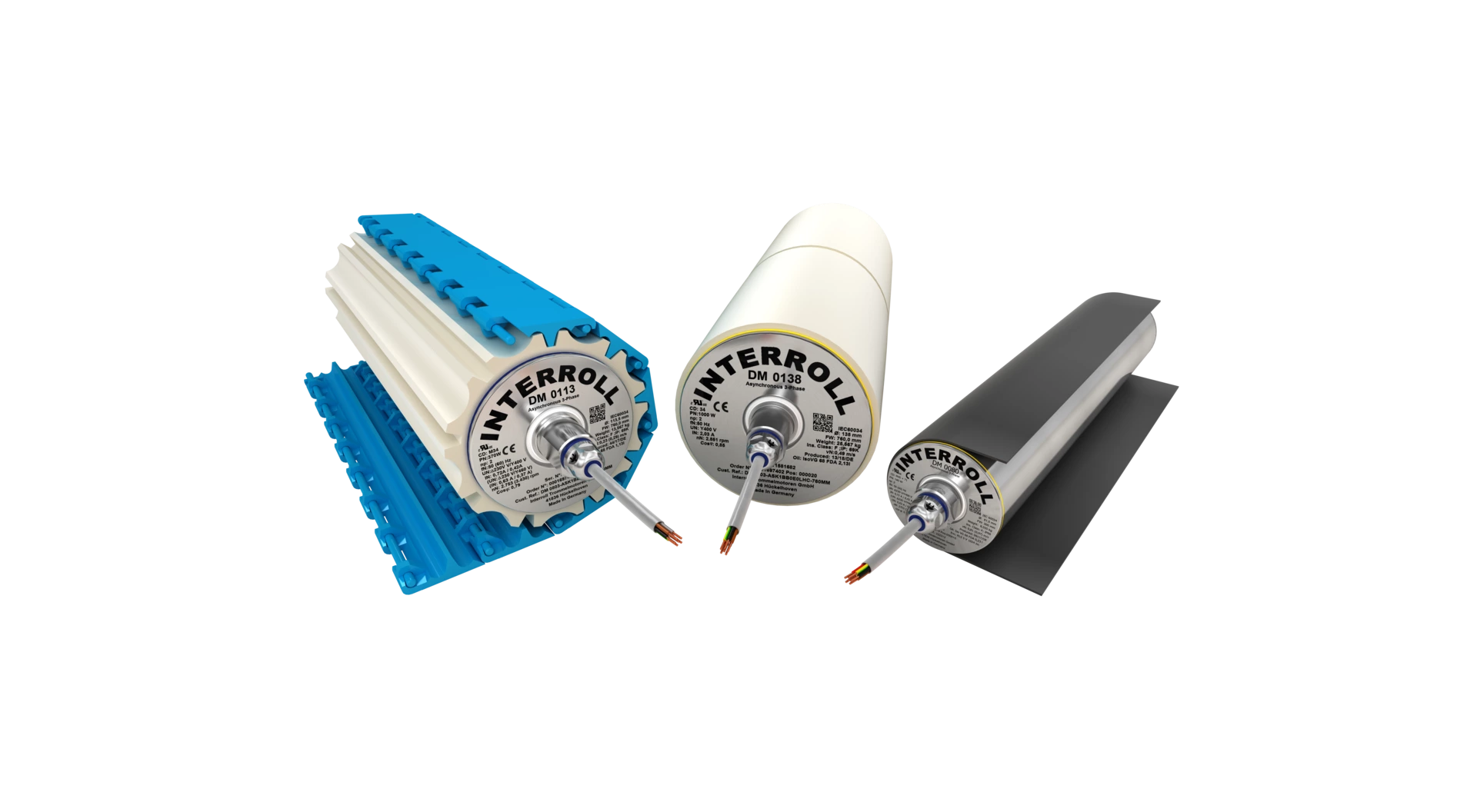

More options, one drive solution: An extended number of gear stages broadens the range of speeds so that one drive solution is sufficient for all current and future uses. Furthermore, all options like encoders, brakes, or backstops are available for all motors.

READ MOREMore performance, more configurations: The extended range of variants for the motors from 40 W to 1100 W covers all conceivable uses in the food industry, material handling, and manufacturing.

Tested quality, innovative technology: All motor components are standardized, and thoroughly tested. For our customers this means shorter delivery times.

Simplified construction, more service, lower costs: Since all motors have the same shafts, the variety of parts is reduced to a Minimum, resulting in a fundamentally easier conveyor construction - no matter if a synchronous motor or an asynchronous motor is needed. Replacement parts are available worldwide through Interroll and service partners provide fast and professional repairs.

Robustness you can rely on

More stable: The 30 mm shaft on Interroll’s new drum motors is significantly stronger, allowing for higher belt Tension as it does not bend even under higher load and at the same time, protects the ball bearings. The customers is on the safe side even with a non-optimal belt tensioning.

READ MOREReliable operation: A stable planetary gear box allows a high torque in all motors, holds up against bending, and resists against overload and impact load. The result is safer, more reliable operation.

Certified quality: All critical components and mechanical connections have been subject to stringent and comprehensive endurance testing. Our engineering laboratory's expertise has been confirmed by practical tests with customers.

All drum motors in the new generation meet the highest requirements and are fitted with the highest degree of IP69k protection, which makes cleaning the facility much faster and easier and also reduces the risk of product contamination in the food processing area.

The PTFE-sealing allows a high pressure cleaning with chemicals according to Diversey specifications.

Faster installation and maintenance

The new drum motor platform is not only easy to operate but also to install, mount, and maintain. The plug-in cable connection serves as a true plug-and-play solution for faster, easier initial installation, maintenance, and repairs.

Complete disassembly is not needed for motor maintenance or the replacement of a damaged cable. Customers save time, lower costs and reduce potential downtime.

Interroll Drum Motors are used as a drive mechanism in belt conveyors. Based on many years of experience, Interroll can offer a comprehensive range of belt drives for a vast array of applications.

Learn more