United States

More countries

Menu

Service

Solutions

Sort

Pick

Convey

Store

Industries

Airports

Courier, Express & Parcel (CEP)

E-Commerce, Retail & Fashion

Food & Beverage

Manufacturing Logistics

Storage & Distribution

Tire & Automotive

Products

Unit Handling

Pallet Handling

Unit Handling

Pallet Handling

Unit Handling

Rollers and Wheels

Drives

Controls

Conveyors

Power Supplies

Sorter

Carton Flow

Pallet Handling

Rollers

Drives

Controls

Modular Pallet Platform

Stacker Crane

Transfer Car

Pallet Flow

Smart Pallet Mover

Tools & Downloads

Tools & Downloads

Software Downloads

Tools & Downloads

Belt Drive Matchmaker - BDMM

CAD Download

Downloads

E-learning

Lifetime Service

Software Downloads

MultiControl

Pallet Control

Company

About Interroll

Technology

Investor Relations

Sustainability

About Interroll

Culture and Values

Corporate Governance

Corporate Compliance

Interroll Academy

Careers

Technology

Centers of Excellence

Innovation Projects and Development Center

Digitalization

MicroHubs

Energy Efficiency

Logistics Industry Outlook

Investor Relations

Ad Hoc Press Releases

Stock Information

Reports and Publications

Annual General Meeting

Financial Calendar

Financial Analysts

Alternative Performance Measures

Investor Relations Contact

News service & Press Contact

Sustainability

Sustainability Management

Sustainable Development Goals

Sustainability Report

ESG Download Center

News & Events

Events

News & Press Releases

E-Moving Magazine

PR material / Gallery

References

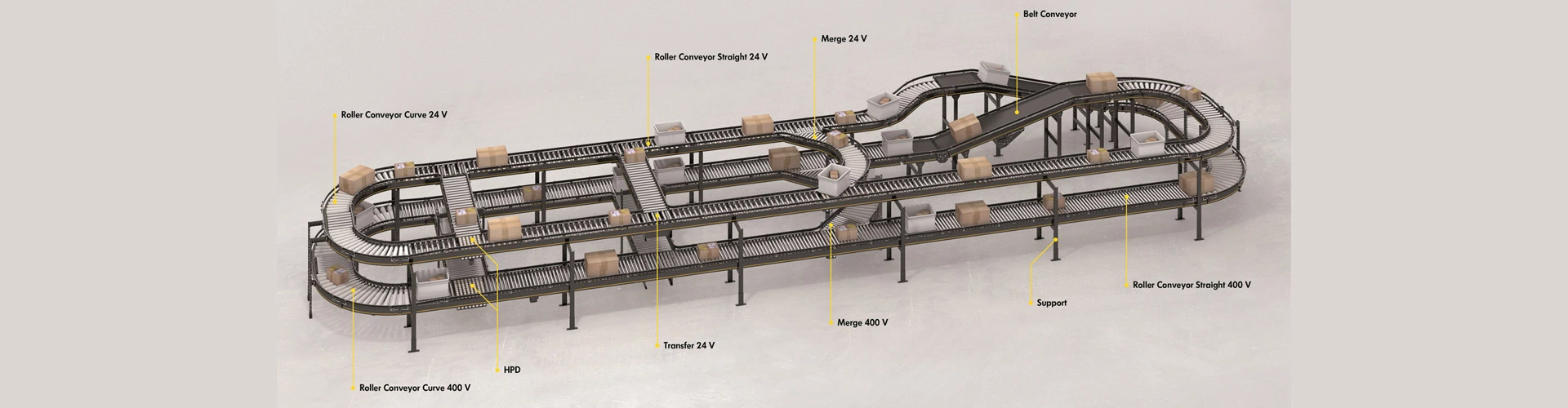

Interroll’s new generation conveyor modules are the most versatile and durable systems available, assuring highest availability and scalability for future growth.

The platform was developed by using a holistic approach to designing each process level – whether the ordering process, the planning of the conveyor system or its installation – as efficiently as possible. The modules themselves set a high standard for reliable and solid technical performance. This platform was designed for flexibility, modularity, attractive industrial design, simple handling during assembly and expansions.

With the conveyor modules in three standard widths, all common materials can be transported reliably. This keeps the expenses for combining different modules into a conveyor solution low and reduces the customer's stocking of spare parts to a minimum.

Customer needs, conditions on site, and type of materials to be conveyed define the requirements for a system. The Interroll conveyor modules can be designed for the most efficient solution for each task. Zero pressure accumulation conveying can be implemented with proven DC RollerDrive. For higher performance, efficient DC drives that enable efficient and future-proof zero pressure accumulation conveying are used together with roller conveyors with 400 V flat belt drives. Pneumatics, which creates high operating costs, is completely omitted here.

Refined technical details and solutions offer lots of room for the flexibility of our customers. If changes to or expansions of the system should be necessary, the planning is simple. Thanks to the modular concept, the individual modules are perfectly matched and can be easily combined with each other.

Largely pre-assembled modules accelerate the installation on site. Independently adjustable side guides, infinitely adjustable supports, integrated electrical conduits and an universally applicable master gauge for holes to attach add-on components are only a few of the details that reduce the installation effort.

The robust and extensively tested design of the conveyor modules reduces the maintenance effort and ensures the reliable operation of a conveyor system. The platform offers a wide selection of modules and key elements so that the material flow can be planned efficiently. Everything from a single source and with expert consultation.

“With their new conveyor platform, Interroll has got it right: modularity and scalability all the way, with plug-and-play modules and standard components. We have been involved in the product development process at an early stage, giving us the possibility to actively contribute ideas and suggest improvements where needed.”

Francis Meier, Managing Director Technology Center

Swisslog AG, Buchs, Switzerland

“Over the past years, energy efficiency has become a key aspect in all our intralogistics projects. With Interroll’s cutting-edge 24V technology and innovative drive systems, we can provide our customers with tailored solutions that guarantee lowest operating and mainte - nance costs and exemplary low-noise operation. The modularity of Interroll’s new conveyor platform will further enhance our product offering.”

Hans-Georg Förster, Managing Director

Förster & Krause GmbH, Remscheid, Germany