United States

More countries

Menu

Service

Solutions

Sort

Pick

Convey

Store

Industries

Airports

Courier, Express & Parcel

Fashion & E-Commerce

Food & Beverage

Manufacturing Logistics

Storage & Distribution

Tire & Automotive

Products

Unit Handling

Pallet Handling

Unit Handling

Pallet Handling

Unit Handling

Rollers and Wheels

Drives

Controls

Conveyors

Power Supplies

Sorter

Carton Flow

Pallet Handling

Rollers

Drives

Controls

Modular Pallet Platform

Stacker Crane

Transfer Car

Pallet Flow

Smart Pallet Mover

Tools & Downloads

Tools & Downloads

Software Downloads

Tools & Downloads

Belt Drive Matchmaker - BDMM

CAD Download

Downloads

E-learning

Lifetime Service

Software Downloads

MultiControl

Pallet Control

Company

About Interroll

Technology

Investor Relations

Sustainability

About Interroll

Culture and Values

Corporate Governance

Corporate Compliance

Interroll Academy

Careers

Technology

Centers of Excellence

Innovation Projects and Development Center

Digitalization

MicroHubs

Energy Efficiency

Logistics Industry Outlook

Investor Relations

Ad Hoc Press Releases

Stock Information

Reports and Publications

Annual General Meeting

Financial Calendar

Financial Analysts

Alternative Performance Measures

Investor Relations Contact

News service & Press Contact

Sustainability

Sustainability Management

Sustainable Development Goals

Sustainability Report

ESG Download Center

News & Events

Events

Press Releases

E-Moving Magazine

News Service & Press Contact

PR material / Gallery

References

Automated and intelligent conveyor technology will change parts of the material handling process in the future.

The digitization of value chains is in full swing. It is well on its way to transforming the material handling industry into a cutting-edge cross-sectional industry and a hotspot for digital transformation. The prospects that the global success of e-commerce as one of the driving forces behind digitization will continue for a long time to come are still excellent. Most sectors of the economy will no longer be able to do without efficient material handling solutions in the future.

In manufacturing and distribution processes, there are clear developments with the "Industrial Internet of Things", which suggest that production and goods storage and distribution will be much more closely networked in the future, right through to mergers.

However – and digitalization is no exception: customers and users of the Interroll solution must always receive a measurable return on investment. At Interroll, we are working to make the rollers smarter and thus create added value for our customers in the form of greater efficiency in material handling and even higher plant availability.

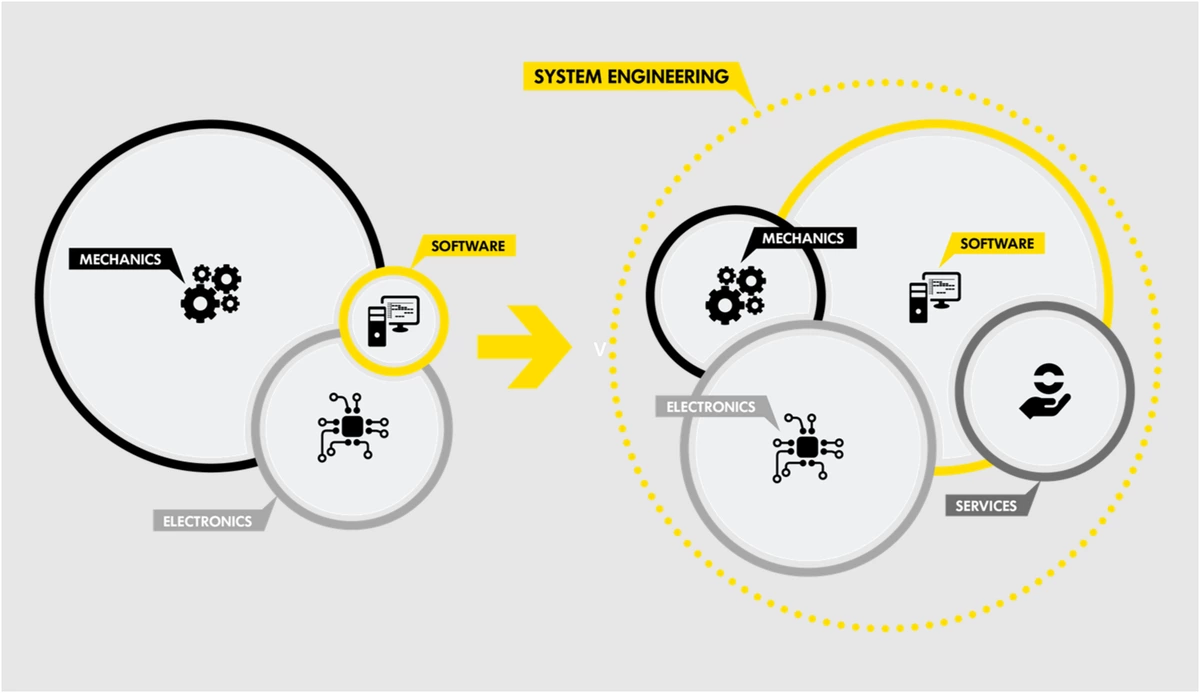

The trend is clear: logic and mechanics are moving closer towards each other and Interroll is already playing a leading role in shaping this process in our industry.

Conveyor technology will be even more automated than before, but also more intelligent. Part of the material handling process will then be controlled at machine level. In future, layout changes can be implemented by reprogramming decentralized intelligence. This will enable conveyor technology to contribute to the development of decentralized intelligence in logistics, distribution and production.

In 2017 and 2018, Interroll therefore invested CHF 5 million each in research budget for innovations in the area of "Logistics 4.0". With our MultiControl, we already offer a certified network card that can control the RollerDrive EC310 in standards such as PROFINET, EtherNet/IP and EtherCat.

With the help of MultiControl, sensors and RollerDrive are integrated directly into the fieldbus level.

Alongside the tried-and-tested analog interface, the EC5000 can be supplied with a bus interface based on the CANOpen standard, upon request. This means that modern conveying systems can offer data transparency for the first time. In combination with an Interroll control system with multi-protocol capability (PROFINET, EtherNet/IP and EtherCat), this means that users can consistently visualize a range of information and functions on the screen using the PLC or a web interface. One example is the display of general information about the current operating state and the operating load of the individual drives over time. In parallel, the control systems enable a range of detailed information such as precise error statuses, torque or temperature, for instance, to be read out for each individual drive.

At the same time, the new RollerDrive's bus interface enables users to carry out completely new control functions that are required in an automated environment. As a result, users can control the acceleration, speed and deceleration of the conveyed goods in the system more precisely. This solution also allows them to position the relevant goods on the conveyor to the nearest millimeter—a key requirement in order to guarantee seamless conveying interplay between the conveyor solution and robots or automated gripper arms.