Insights

Die vielen Vorteile der virtuellen Logistik

Ein Interview mit Professor Dr. Philipp Rauschnabel von der Universität der Bundeswehr München über Augmented Reality (AR) und Virtual Reality (VR) in der…

Wo stecken die Anwendungsschwerpunkte für VR bzw. AR?

Philipp Rauschnabel: VR ist sehr vorteilhaft bei der Planung von Anlagen und der Schulung. So lässt sich ein Fließband simulieren, an dem neue Mitarbeiter die Arbeitsschritte lernen. Der Vorteil: Bei einer Fehlbedienung bleibt nicht gleich das ganze Band stehen – immerhin braucht man überhaupt kein echtes Fließband. AR eignet sich für Arbeitsanweisungen sehr gut. Viele „moderne“ Produktionsanlagen haben Screens in Sichtweite, auf denen erklärt wird, wie das Produkt auszusehen hat. Doch die Arbeiter müssen diese abstrakten Anweisungen auf das echte Produkt vor sich beziehen, dadurch entstehen noch Fehler. AR kann die Anweisungen („Diese Schraube in das vierzehnte Loch von links“) direkt dort einblenden, wo die Information gebraucht wird („Dieses Loch hervorheben“). Ähnliches gilt für die Montage neuer Anlagenkomponenten. Auch Wartungsaufgaben lassen sich so begleiten. Oder ein externer Experte schaltet sich live ein.

Trotzdem werden solche Möglichkeiten selten realisiert. Was verhindert die Implementierung?

Abgesehen von einer grundsätzlichen Zurückhaltung gegenüber innovativen Technologien in manchen Unternehmen erschweren vor allem zwei Faktoren eine Umsetzung: Zum einen fühlt sich oft niemand für die strategische Integration von AR im Unternehmen zuständig. Nicht selten hat der CEO das Thema auf einer Konferenz „entdeckt“ und will es deshalb – statt von einem Problem auszugehen, für das AR die Lösung wäre. Das andere Hindernis liegt oft in der fehlenden Einbindung der Anwender, das schürt Ressentiments.

Google Glass war seinerzeit eine Sensation, hat sich aber nicht durchsetzen können. Gibt es da nicht neue Ansätze?

Google Glass ist lediglich vom Konsumentenmarkt verschwunden – denn es gab ein eher fragwürdiges Design, keinen echten Mehrwert im Alltag. Aber im Enterprise-Bereich ist sie noch immer im Einsatz und es gibt mittlerweile auch eine Weiterentwicklung.

Wohin geht denn auf der Hardwareseite die Reise?

Die Devices werden häufig als zu groß und zu schwer empfunden, man möchte sie nicht länger aufsetzen. Die neuesten Modelle sind jedoch wesentlich kleiner und leichter, sie lassen sich eine Stunde oder länger tragen. Die Zukunft sind vor allem Glasses verschiedener Hersteller. Google, Microsoft und Apple, aber auch viele kleinere Spezialisten, sind da dran. Noch in weiter Zukunft sind auch Kontaktlinsen denkbar.

Dazu gibt es zunehmend Tiefensensoren in Mobile Devices. Die werden wohl bald Standard in vielen Tablets und Smartphones sein, mit denen man einen Raum scannen und ein 3D-Modell erstellen kann. Apple und Facebook sind sehr am Konsumentenmarkt interessiert, aber andere Devices – etwa von Epson oder Microsoft – zielen zunächst primär auf den Enterprise-Sektor. Diese Entwicklung ist vergleichbar mit Laptops oder Handys, die auch erst einmal Enterprise-Technologien gewesen sind.

Ein ganz wichtiger Punkt ist 5G. Denn der Trend geht dahin, dass auf dem Device selbst gar nicht mehr so viel geschieht, sondern dass der Livestream der Sensoren an Rechner geschickt, dort verarbeitet und zurückgeschickt wird. Damit werden Latenzen interessant, denn das muss alles in Echtzeit geschehen. Deshalb ist es eine Lösung, den Server möglichst nahe zu platzieren und nicht hunderte Kilometer entfernt.

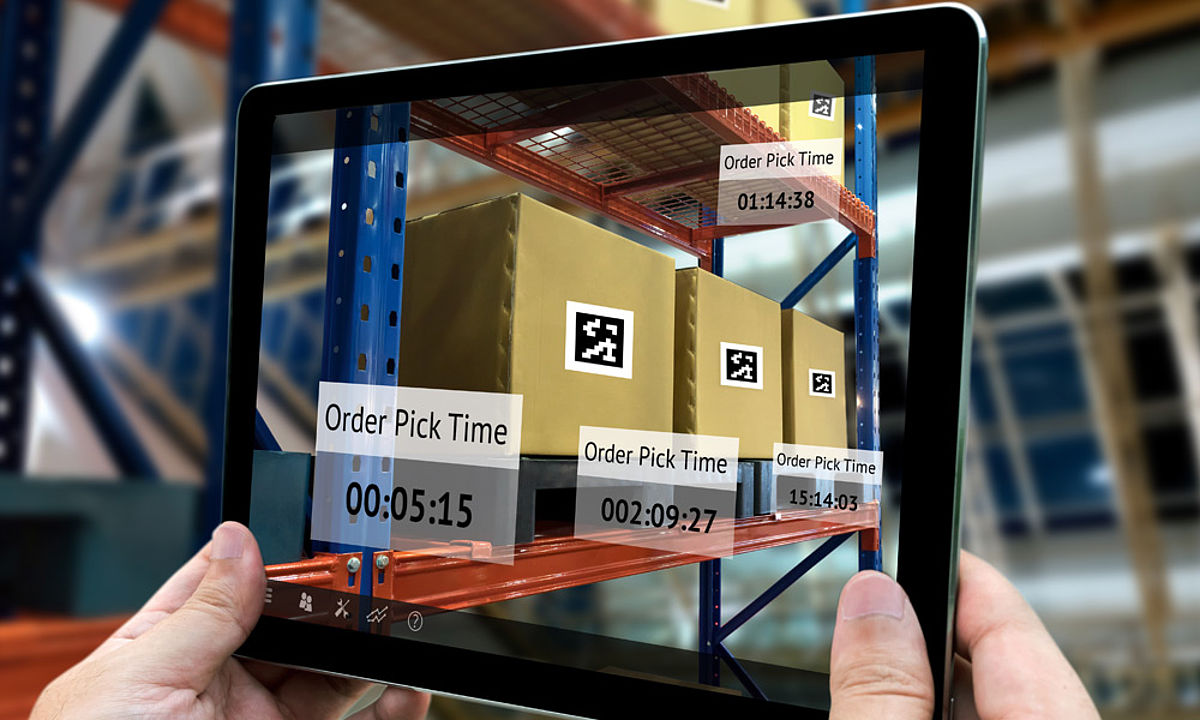

In Logistik und Lagerhaltung ist die Digitalisierung ja schon weit fortgeschritten, Stichwort „Pick by Vision“. Aber gibt es auch ganz andere Möglichkeiten?

Bei der Neueinrichtung einer Halle mit Elementen, die sich bewegen, kann man beispielsweise das CAD-Modell eines Roboters in die AR-Lösung packen und virtuell in der Fabrikhalle platzieren. Damit lässt sich sehr gut zeigen, wie weit der Arm ausschwenkt, welchen Raum er benötigt und so weiter.

Können AR/VR auch den Mensch-Maschine-Dialog vereinfachen?

Ja. Denn Menschen denken 3-dimensional, bisherige Anwendungen sind aber auf 2D-Screens beschränkt. Die Herausforderung liegt nun darin, die Schnittstelle zum Menschen sinnvoll auszugestalten.

Wie kann man sich das etwa bei der Installation eines neuen Sorters vorstellen? Wo liegen da die besonderen Vorzüge von AR?

Schon bei der Planung: Wie sieht das Gerät virtuell in der realen Halle aus? Wieviel Platz nimmt es ein, erreiche ich noch alle Türen und so weiter? Oder beim Aufbau und der Wartung: Die Monteure können Anweisungen direkt über die Brille erhalten. Wir arbeiten gerade an einem Projekt, bei dem Arbeiter die Platzierung der einzelne Soll-Zustände über das Device gezeigt bekommen, zugleich wird jeder Arbeitsschritt mit Foto dokumentiert. Der Leiter kann sich in die Kamera schalten, um zu sehen, ob alles richtig ausgeführt wird. Bei Fragen lässt sich ein Experte zuschalten, der dann via Datenbrille Erläuterungen gibt.

Wird also kein Fachmann mehr vor Ort gebraucht wird?

Man kann die guten Mitarbeiter weit effizienter einsetzen. Das heißt auch, dass Reisezeiten wegfallen, denn die verbringen vielleicht 30 Prozent der Woche allein mit Fahrten zum Kunden. Mit AR können sie aus der Ferne die Installation oder Reparatur dirigieren und müssen nur bei echten Notfällen ausrücken.

Wird der virtuelle Cyborg das menschliche Zukunftsmodell?

Generell verschwinden die Grenzen zwischen Mensch und Technologie. Das erkennt man zum einen an der Anthropomorphisierung von Technologien wie „Siri“, „Alexa“, humanoide Roboter – die, ein netter Nebeneffekt, übrigens vorsichtiger bedient werden als nicht-menschliche. Andererseits: Autofahren ohne Navigationssystem ist fast nicht möglich, man kann auf das mühsame Kartenlesen verzichten. Das spart unnötige Denkleistung. Im Produktionsprozess kann das bedeuten, dass auch ungelernte Arbeiter komplexere Tätigkeiten übernehmen können, weil sie Schritt für Schritt Anleitungen bekommen.

Zur Person:

Prof. Dr. Philipp A. Rauschnabel ist Professor für Digitales Marketing und Medieninnovation an der Universität der Bundeswehr München. In der Forschung beschäftigt sich Prof. Dr. Rauschnabel mit dem Einsatz dieser Technologien im Marketing und anderen Bereichen, wie zum Beispiel Produktion und Training. Zuvor arbeitete er als Assistant Professor an der University of Michigan - Dearborn bereits an diesen Themen.

Interroll setzt auf Google Glass

Interroll Spanien und Siemens arbeiteten gemeinsam an einem Crossbelt-Sorter-Projekt in Guarroman, Spanien. Anwender war Nacex, ein Anbieter von Expresskurierdiensten in Spanien, Andorra und Portugal. Als es jedoch an der Zeit war, den Sorter zu installieren, stellten die Corona- Reisebeschränkungen eine große Hürde dar, da das Interroll-Installationsteam normalerweise aus Deutschland kommen würde.

Interroll Spanien entschied sich deshalb für einen neuen innovativen Ansatz, bei dem erstmals Google Glass zum Einsatz kam. Das spanische Team vor Ort wurde durch deutsche Kollegen aus der Ferne unterstützt. Google Glass erwies sich als äußerst praktisch und wird ein integraler Bestandteil des Interroll Lifetime Service Programms für zukünftige Installations- und Wartungsarbeiten.