United States

More countries

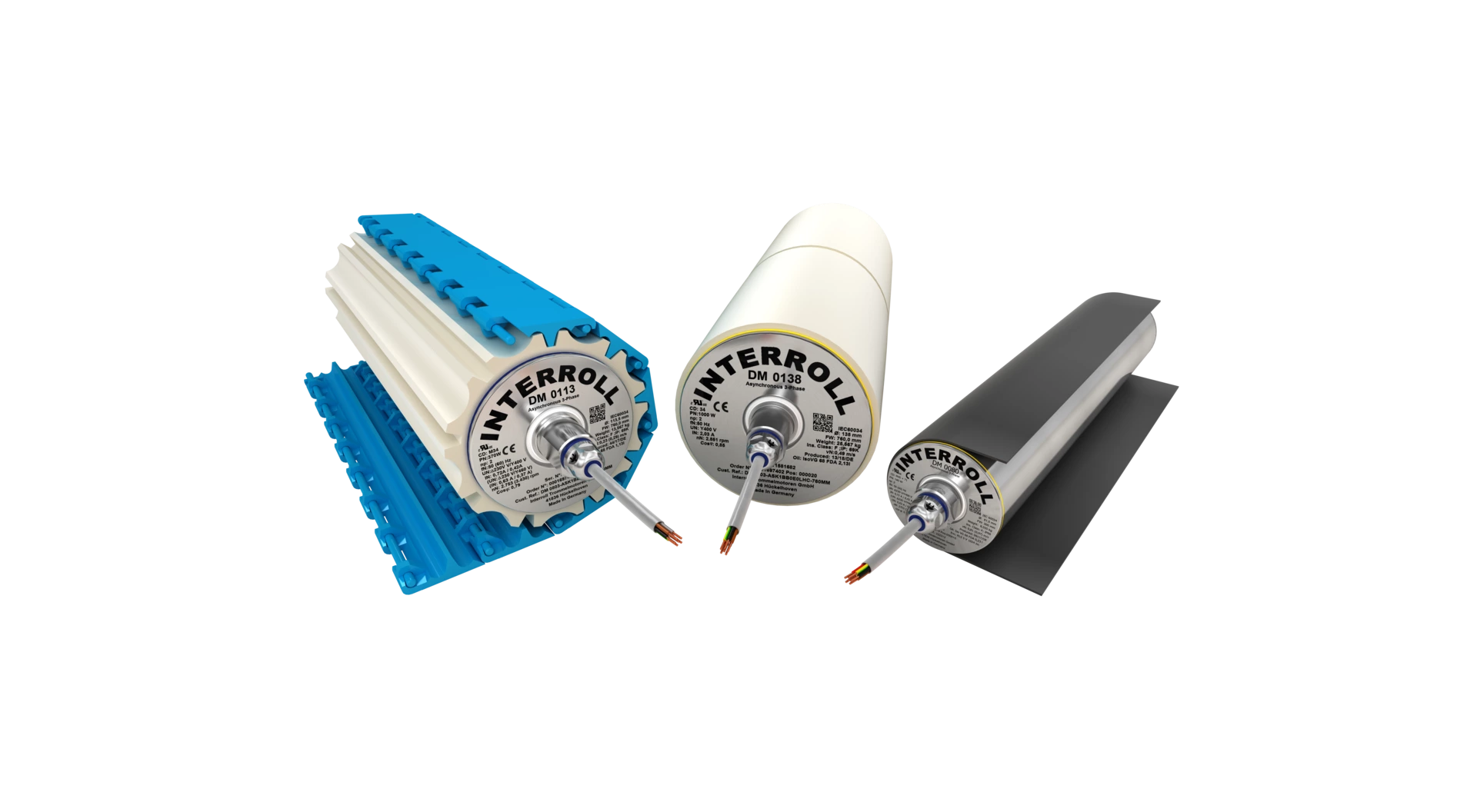

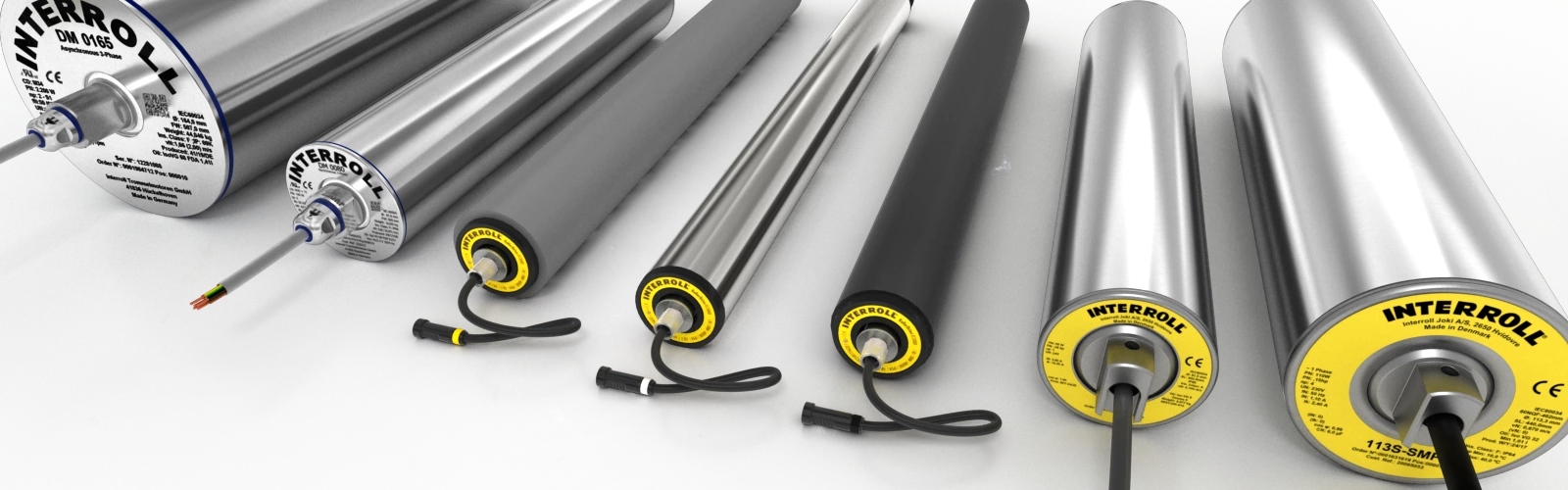

Our RollerDrive and drum motors offer the exact drive for every conveyor system. Drum motors are designed for use in belt conveyors and conveyor systems. They are installed directly in the frame of the conveyor to save space. The wide speed range covers a wide variety of applications, e.g. in industry as well as in food processing, baggage handling, supermarket checkouts and empty goods systems. RollerDrive is designed to drive roller and belt conveyors. The DC motor rollers are used in zero pressure accumulation conveyor systems as well as in continuous conveyors.

The powerful motorized roller for roller and belt conveyors.

50 Watt, 48V and bus interface.

The RollerDrive EC5000 with 50 watt power consumption, 48V voltage and bus interface ensures that even heavy goods are transported without accumulation pressure.

Learn more

The powerhouse of modern belt conveyors.

Compact, powerful, energy efficient and ultra-hygienic.

The asynchronous and synchronous drum motors of the DM 0080 series cover all areas of application - even in hygienically sensitive environments.

Learn more

Wide range of speeds.

The drum motor for every situation.

The DM 0113 series drum motors are suitable for all conceivable belt conveyor applications - available in asynchronous or synchronous design.

Learn moreWith the market launch of the new Interroll DC Platform, Interroll is expanding its range of coordinated material handling solutions. RollerDrive, controls and power supplies are designed to enable system integrators and plant engineers to meet their customers' requirements even more precisely - from standard applications to plants with industrial 4.0 functionality.