United States

More countries

Menu

Service

Solutions

Sort

Pick

Convey

Store

Industries

Airports

Courier, Express & Parcel

Fashion & E-Commerce

Food & Beverage

Manufacturing Logistics

Storage & Distribution

Tire & Automotive

Products

Unit Handling

Pallet Handling

Unit Handling

Pallet Handling

Unit Handling

Rollers and Wheels

Drives

Controls

Conveyors

Power Supplies

Sorter

Carton Flow

Pallet Handling

Rollers

Drives

Controls

Modular Pallet Platform

Stacker Crane

Transfer Car

Pallet Flow

Smart Pallet Mover

Tools & Downloads

Tools & Downloads

Software Downloads

Tools & Downloads

Belt Drive Matchmaker - BDMM

CAD Download

Downloads

E-learning

Lifetime Service

Software Downloads

MultiControl

Pallet Control

Company

About Interroll

Technology

Investor Relations

Sustainability

About Interroll

Culture and Values

Corporate Governance

Corporate Compliance

Interroll Academy

Careers

Technology

Centers of Excellence

Innovation Projects and Development Center

Digitalization

MicroHubs

Energy Efficiency

Logistics Industry Outlook

Investor Relations

Ad Hoc Press Releases

Stock Information

Reports and Publications

Annual General Meeting

Financial Calendar

Financial Analysts

Alternative Performance Measures

Investor Relations Contact

News service & Press Contact

Sustainability

Sustainability Management

Sustainable Development Goals

Sustainability Report

ESG Download Center

News & Events

Events

Press Releases

E-Moving Magazine

News Service & Press Contact

PR material / Gallery

References

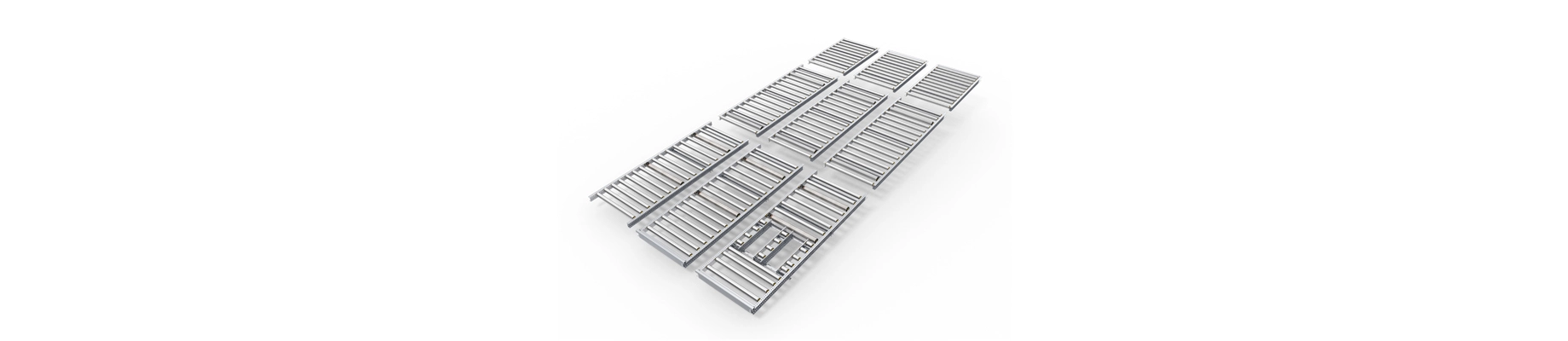

From FIFO (First In - First Out) to LIFO (Last In - First Out) applications, from the buffer section to the picking and shipping section – Interroll offers a wide range of products.

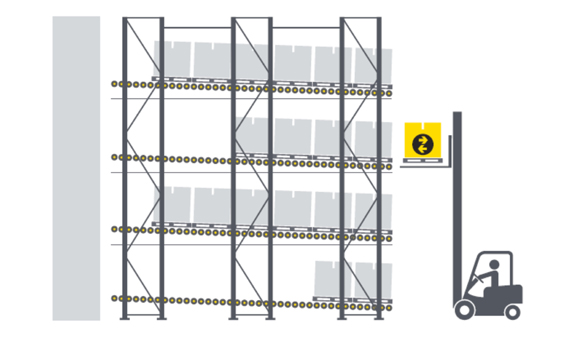

In FIFO configuration (First In - First Out), the pallets are loaded in the gravity lanes on the entry side (the highest point). The slope then carries the pallets from the loading point to the retrieval point. When a pallet is unloaded, the next pallet automatically takes its place thereby ensuring that the goods are constantly available.

FIFO stock management guarantees stock rotation as the first pallet to be loaded in a lane is the first pallet available at the picking face on the retrieval side. This management method is particularly efficient for perishable goods.

In LIFO configuration (Last In - First Out), a forklift truck loads and unloads the pallets at the picking face. This is a pushback system. To load a pallet, the forklift truck pushes the pallet at the picking face towards the back of the lane using the pallet to be loaded.

When a pallet is unloaded, the pallet stored behind automatically takes its place, thereby ensuring that the goods are constantly available at the picking face.