United States

More countries

Menu

Service

Solutions

Sort

Pick

Convey

Store

Industries

Airports

Courier, Express & Parcel

Fashion & E-Commerce

Food & Beverage

Manufacturing Logistics

Storage & Distribution

Tire & Automotive

Products

Unit Handling

Pallet Handling

Unit Handling

Pallet Handling

Unit Handling

Rollers and Wheels

Drives

Controls

Conveyors

Power Supplies

Sorter

Carton Flow

Pallet Handling

Rollers

Drives

Controls

Modular Pallet Platform

Stacker Crane

Transfer Car

Pallet Flow

Smart Pallet Mover

Tools & Downloads

Tools & Downloads

Software Downloads

Tools & Downloads

Belt Drive Matchmaker - BDMM

CAD Download

Downloads

E-learning

Lifetime Service

Software Downloads

MultiControl

Pallet Control

Company

About Interroll

Technology

Investor Relations

Sustainability

About Interroll

Culture and Values

Corporate Governance

Corporate Compliance

Interroll Academy

Careers

Technology

Centers of Excellence

Innovation Projects and Development Center

Digitalization

MicroHubs

Energy Efficiency

Logistics Industry Outlook

Investor Relations

Ad Hoc Press Releases

Stock Information

Reports and Publications

Annual General Meeting

Financial Calendar

Financial Analysts

Alternative Performance Measures

Investor Relations Contact

News service & Press Contact

Sustainability

Sustainability Management

Sustainable Development Goals

Sustainability Report

ESG Download Center

News & Events

Events

Press Releases

E-Moving Magazine

News Service & Press Contact

PR material / Gallery

References

Interroll's Modular Pallet Conveyor Platform MPP can now even handle very heavy pallets weighing 1,500 kilograms. In addition, a particularly energy-efficient expansion variant using 48V RollerDrive and MultiControl controllers now also allows medium-weight goods of up to 500 kilograms to be moved without accumulation pressure.

Pallet weight

Up to 500 kg Up to 1500 kg Up to 1200 kg11

products match your selection.

Apply next filter or go here to the products.

Conveyor Type

Roller Conveyor Chain Conveyor11

products match your selection.

Apply next filter or go here to the products.

Conveying Way

Straight 270 ° rotation11

products match your selection.

Apply next filter or go here to the products.

Direction of conveying

Straight 90° discharge 270 ° rotation11

products match your selection.

Apply next filter or go here to the products.

Pallet weight

Up to 500 kg Up to 1500 kg Up to 1200 kg11

products match your selection.

Apply next filter or go here to the products.

Conveyor Type

Roller Conveyor Chain Conveyor11

products match your selection.

Apply next filter or go here to the products.

Conveying Way

Straight 270 ° rotation11

products match your selection.

Apply next filter or go here to the products.

Direction of conveying

Straight 90° discharge 270 ° rotation11

products match your selection.

Apply next filter or go here to the products.

Find your drive

These 11 products perfectly meet your requirements.

product-slider

11

products match your selection.

Apply next filter or go here to the products.

Maximum Space Utilization

HIGH DYNAMICS AND COMPACT STACKER CRANE.

The best and most efficient way to optimize storage space in a warehouse or DC is to go vertical and make the best use of the available volume, rather than utilizing more floor area.

Learn more

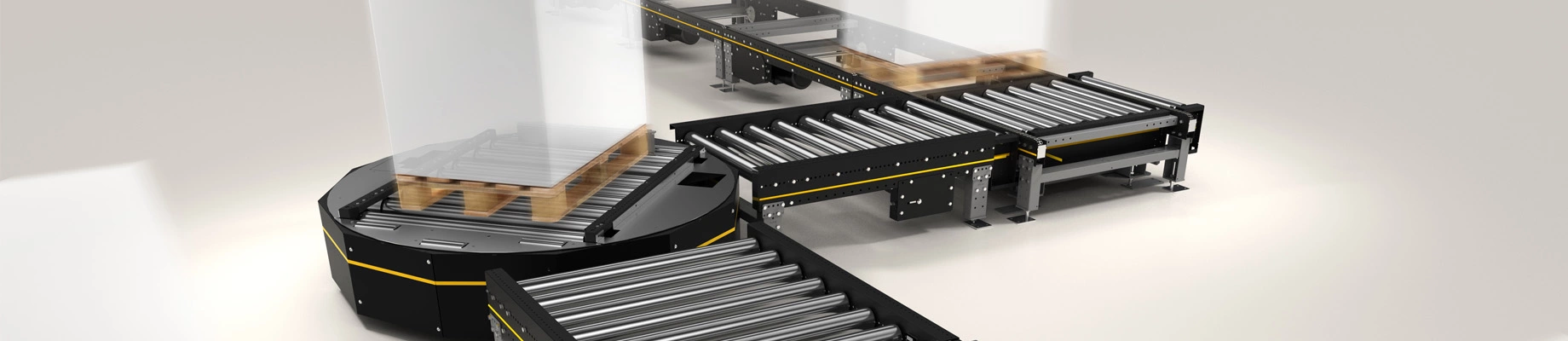

The best of both worlds.

The pallet conveyor with RollerDrive.

The compact PM 9712 roller conveyor is driven by a 48V RollerDrive. With a MultiControl control system, a zero pressure accumulation pallet conveyor system is created quite simply.

Learn more

Ideal combination.

Uniform control unit for 400 V and 24/48 V drives.

The simple combination of the Pallet Control PC 6000 with the MultiControl creates a universal control concept for the complete pallet conveyor system. This considerably reduces the planning and installation effort.

Learn moreThe New Modular Pallet Conveyor Platform MPP is a versatile solution for pallet handling. Combined with the company’s proven dynamic storage storage solution, Interroll’s new pallet conveyor platform provides the ideal basis for creating comprehensive storage and conveyor solutions for all kinds of applications.