United States

More countries

Menu

Service

Language

Solutions

Sort

Pick

Convey

Store

Industries

Airports

Courier, Express & Parcel

Fashion & E-Commerce

Food & Beverage

Manufacturing Logistics

Storage & Distribution

Tire & Automotive

Products

Unit Handling

Pallet Handling

Unit Handling

Pallet Handling

Unit Handling

Rollers and Wheels

Drives

Controls

Conveyors

Power Supplies

Sorter

Carton Flow

Pallet Handling

Rollers

Drives

Controls

Modular Pallet Platform

Stacker Crane

Transfer Car

Pallet Flow

Smart Pallet Mover

Tools & Downloads

Tools & Downloads

Software Downloads

Tools & Downloads

Belt Drive Matchmaker - BDMM

CAD Download

Downloads

E-learning

Lifetime Service

Software Downloads

MultiControl

Pallet Control

Company

About Interroll

Technology

Investor Relations

Sustainability

About Interroll

Culture and Values

Corporate Governance

Corporate Compliance

Interroll Academy

Careers

Technology

Centers of Excellence

Innovation Projects and Development Center

Digitalization

MicroHubs

Energy Efficiency

Logistics Industry Outlook

Investor Relations

Ad Hoc Press Releases

Stock Information

Reports and Publications

Annual General Meeting

Financial Calendar

Financial Analysts

Alternative Performance Measures

Investor Relations Contact

News service & Press Contact

Sustainability

Sustainability Management

Sustainable Development Goals

Sustainability Report

ESG Download Center

News & Events

Events

Press Releases

E-Moving Magazine

News Service & Press Contact

PR material / Gallery

References

Interroll's new Modular Conveyor Platform (MCP) for chilled and deep-freeze environments, with decentrally controlled RollerDrive drive technology, expands the range of applications of the company's conveyor solutions. Deep-freeze logistics can now benefit from an efficient, zero pressure accumulation (ZPA) material flow down to minus 30 degrees Celsius. This can reduce manual labor in deep-freeze temperatures and leads to a better and safer working environment.

The new deep-freeze MCP offers flexible and scalable configuration with standard plug-and-play components. It accommodates all conveying needs and offers flexibility for future growth. End users benefit from low energy consumption leading to savings in operational cost. The new solution has been tested in several conditions and ambient temperatures and has proven to be a solution perfectly suitable to harsh temperatures.

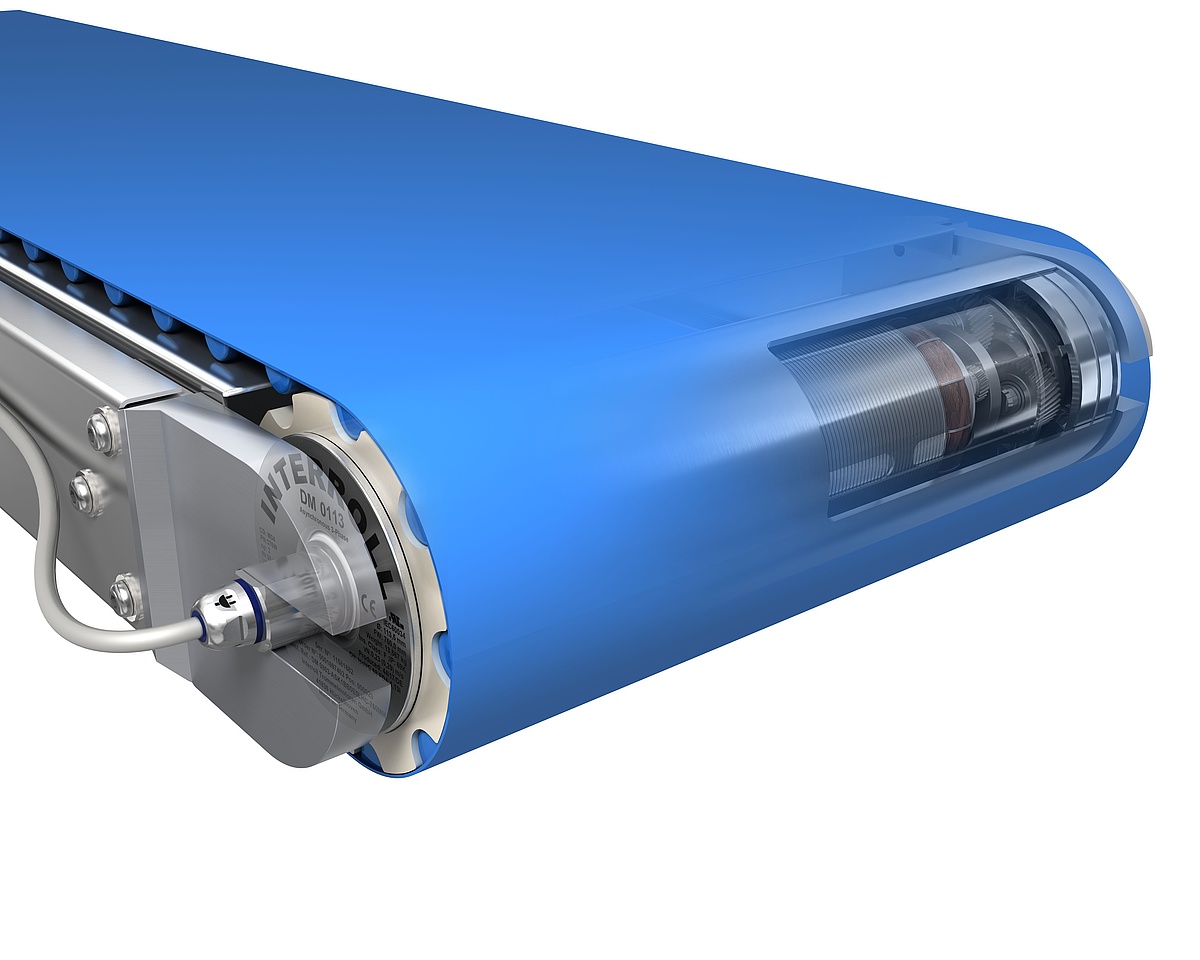

A further highlight will be the new generation of drum motors, which Interroll is now expanding with more diameter options. Interroll will showcase the DM0113 and the DM0138—the latest additions to its range of drum motors—at ANUGA FoodTec. The new generation of drives offers an impressive range of benefits: Stronger shafts and ball bearings ensure particularly long service life and the extremely stable planetary gear design allows high torques to be transferred with low levels of operating noise. All of the new-generation drum motors comply with the requirements of IP69K, the highest degree of hygiene protection; that means they are significantly quicker and easier to clean in comparison to traditional gear motors.

Visit the Interoll booth in in hall 10.1, booth 28.

Contact:

Martin Regnet

Interroll (Schweiz) AG

Global PR Manager

Via Gorelle 3 │ 6592 Sant'Antonino │ Switzerland

+41 91 850 25 21