“New and interesting sectors are emerging”

17.03.2022

Interview as PDF

For Interroll, the Asia-Pacific region is one of the world regions offering attractive growth prospects for business. What developments are shaping the region’s markets? How does the company intend to continue its successful course there as an equipment supplier for material-handling solutions? Interroll Executive Vice President Dr Ben Xia, who is responsible for the Group’s activities in Asia, explains.

Dr. Xia, how did the past financial year in Asia go?

Ben Xia:The positive development of recent years has continued: We achieved strong double-digit growth in order intake, increased our sales and were also able to further increase our value contribution to the Group. We are very pleased that our customers appreciate our technological offering and our work, which enable them to achieve significant productivity gains. Our team in Asia has been successful in establishing the new solutions that Interroll has introduced in the market in recent times. For the demanding and growing Asian markets, our long-term innovation strategy is paying off: We have exactly the right offering on the market today.

Which platforms are we talking about?

First and foremost, our sorters and the DC Platform, which is an ideal complement to the Modular Conveyor Platform (MCP) or other conveyors. It offers our customers – system integrators and original equipment manufacturers – a high level of added value. Thanks to their different performance levels, our family of RollerDrive solutions can be used precisely for a wide range of applications. As a customer and user, you therefore get exactly what you need. In conjunction with the MultiControl, they create controlled, zero- pressure-accumulation material flows that can be seamlessly integrated into modern warehouse management systems – in a very energy-efficient manner.

Keyword energy: On other continents, sustainability plays an increasingly important role for companies. In Asia, too?

Yes, this argument is becoming increasingly important – especially in China. In our case, it’s not just about the high energy efficiency of our drive solutions and the zero-pressure-accumulation conveying concept, but also about the high reliability and long operational life of our technologies. This clearly saves resources. With our proven quality strategy, we provide additional longterm benefits and therefore value for our customers.

“Thanks to their different performance levels, our family of RollerDrive solutions can be used precisely for a wide range of applications. As a customer and user, you therefore get exactly what you need.”

Is e-commerce still the most important driver for the material-handling industry in Asia as well?

Yes, definitely. The already rapid momentum in this area – as in most Western countries – has been accelerated once again by the COVID-19 pandemic. Now, the sheer volume of the flow of goods to be handled every day means that material flow processes can only be managed by automation – even in those countries of our continent where labor costs are traditionally rather low. We can, of course, provide our customers with excellent support in this inevitable upheaval. But there are new, interesting sectors emerging: One example is the production environment, especially the mass production of accumulators for partially or fully electric vehicles in China. This is where our most powerful RollerDrive variants fit very well. Another example relates to food processing, especially employee catering in companies or other organizations. Here we see that the delivery of fresh or chilled meals, which are simply heated up on-site, is now gaining acceptance on a broad front compared to classic canteens. This usually requires providers to supply large volumes of prepared food in a very short time. This is an exciting market that can be served even more specifically in the future with our new solutions for hygienic applications.

And how do you intend to achieve the growth you have planned?

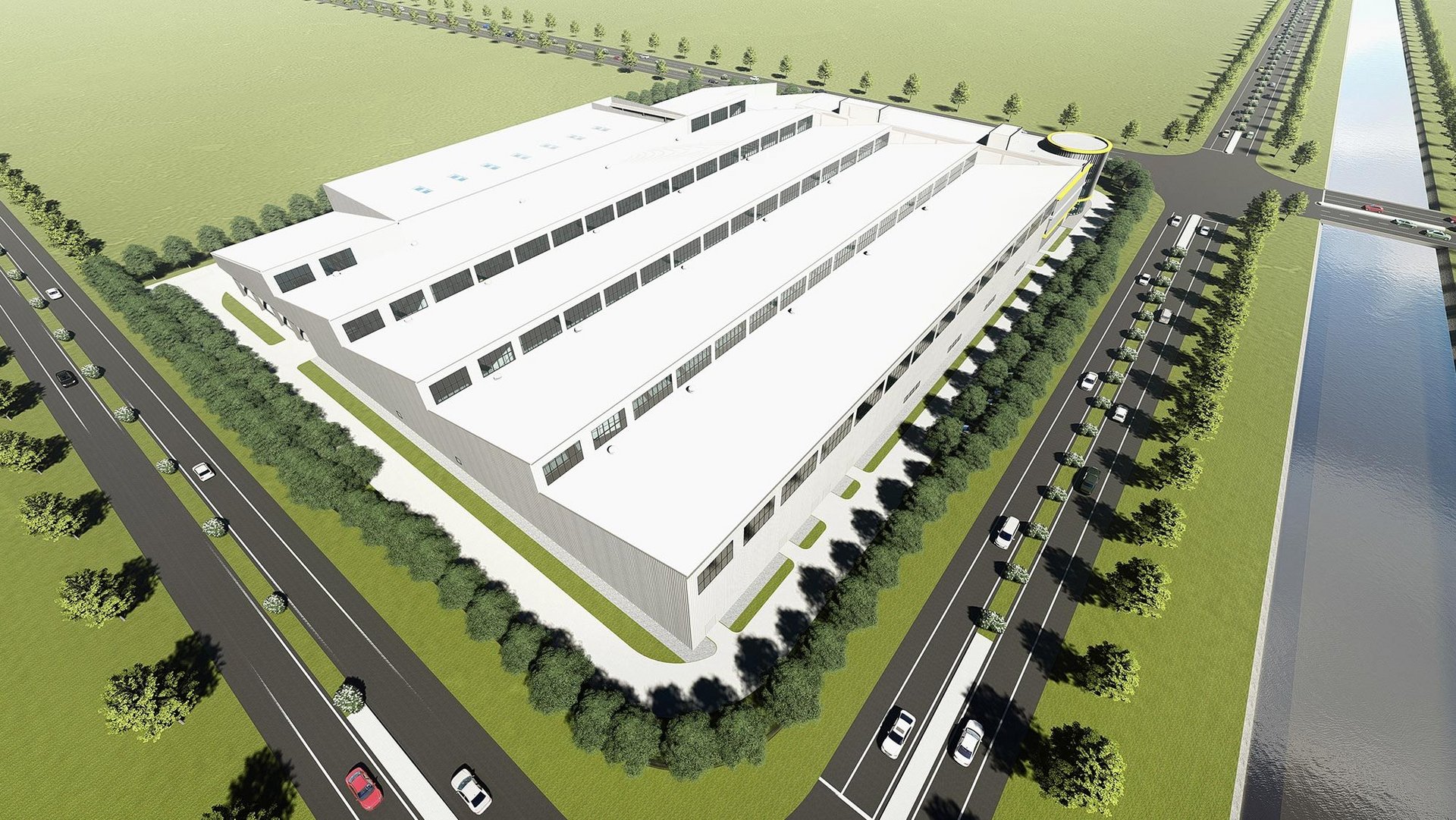

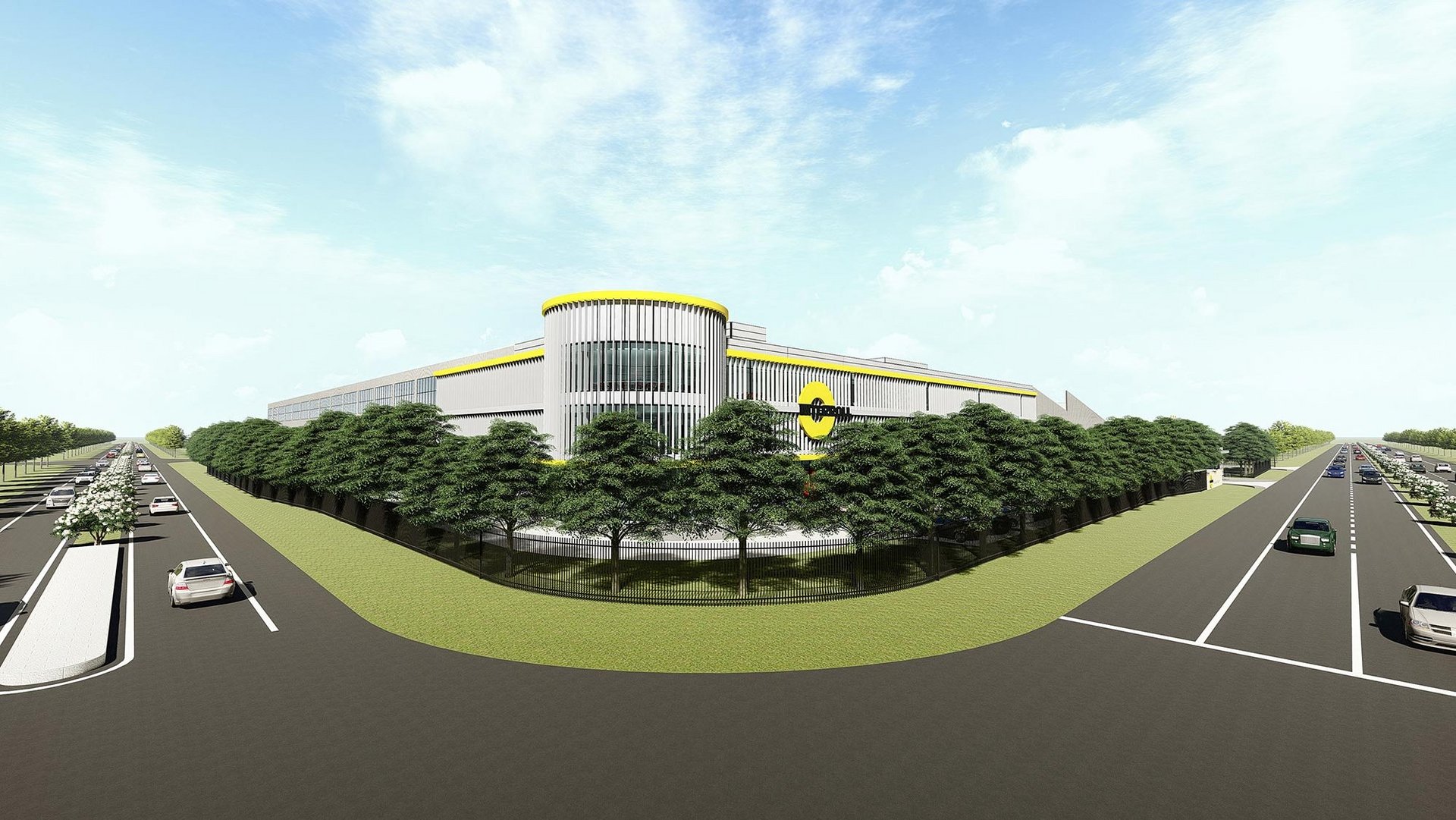

By investing in a new plant, which we announced some time ago. The Interroll Group has provided around EUR 25 million for this purpose. The construction work for the new plant has gone according to plan – also in terms of costs. With the opening of our new site in Suzhou Industrial Park, just 12 kilometers away from the existing site, we are doubling our production capacity at one go and significantly improving our ability to deliver not only in China but also in Asia. After all, we already generate around half of our sales outside China. Moreover, these are also important investments in our competence, because in Suzhou, as a regional Center of Excellence, we will in the future manufacture the Group’s complete product range, with the exception of the production of our belt curve in Shenzhen. But manufacturing capacity and delivery times are not the only advantages offered by the new site in Suzhou.

Tell us more.

One decisive factor in this investment is the fact that we now own the facility. This sends a clear signal that Interroll is really committed to China in the long term. This creates confidence and a strong tailwind for our future business. In addition, the architectural appearance alone, which consistently follows our Group guidelines, strengthens the brand and allows visitors to experience our claim to leadership comprehensively at first glance.

So, the new site in Suzhou is more than just about production?

Yes, absolutely. We now also have exhibition areas there, where we can demonstrate the benefits of our offering live to prospective and current customers and end users. We also have training and education facilities there, so that we can explain our solutions even better to our partners and accelerate training and development of our own employees. And last but not least, the working environment for our employees will also improve significantly and set new standards. This will also be a great asset when we attract new people for our long-term growth, new experts and fresh talent for an exciting future to come.

“This creates confidence and a strong tailwind for our future business.”

Around the world, the pandemic has also affected the economy. At present, many supply chains are still not running as they should. What is the situation in Asia?

At the beginning of the pandemic, it was very important that we in the Group management did not overreact but did everything necessary to support our customers. We follow all hygiene regulations very rigorously, so that we have had practically no restriction of production in China. The procurement market is, of course, tight in Asia, as it is all over the world. However, our team was able to overcome the greatest difficulties with outstanding commitment. In this situation, it is important to communicate with your customers in an open, transparent and trusting manner. Supply chain challenges can only be overcome together with your business partners.

And apart from China, which other markets are interesting at the moment?

South Korea is traditionally an important market for us. Here, for example, we were able to further expand our relationship with an important e-commerce supplier through follow-up orders last year. The Japanese market, which is considered very challenging in intralogistics, is also particularly interesting. Another highlight is Australia, where we won orders for two modern sorting systems last year.